Moldflow Analysis

We understand a successful project lies in meticulous planning and optimisation.

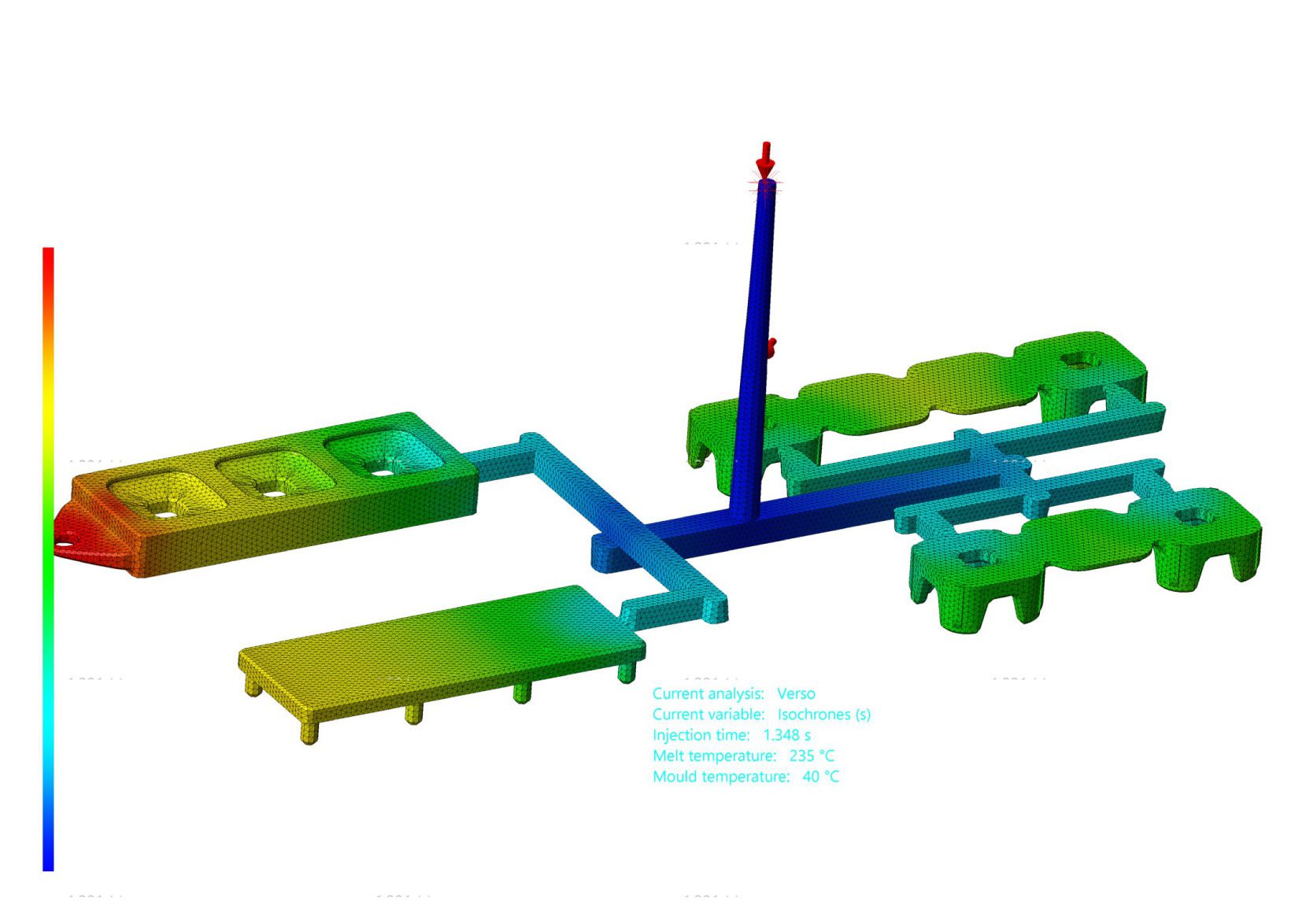

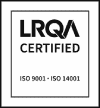

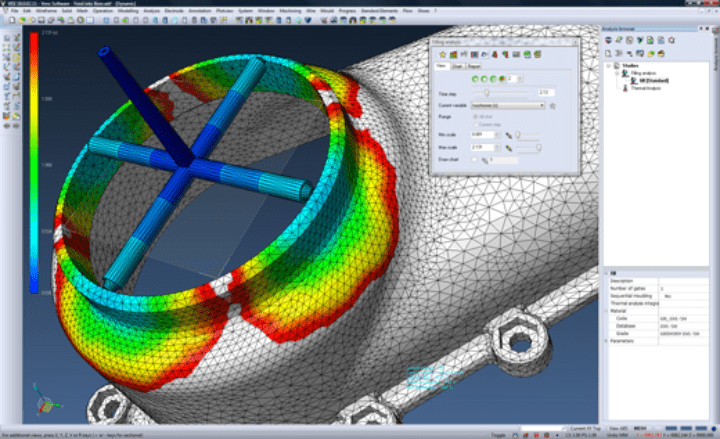

Our Moldflow Analysis Service is a critical component of this process, offering a comprehensive assessment of how a plastic part will fill, cool, and warp in the mould during the injection moulding process.

This advanced analysis is crucial for identifying potential manufacturing challenges and design improvements early in the toolmaking process, ensuring the highest quality and efficiency of the final product.

Looking for a Moldflow Analysis Expert?

Why You Need Moldflow Analysis

Moldflow analysis allows for the detailed simulation of the injection moulding process, providing invaluable insights into potential issues such as:

- Sink marks

- Draft angles

- Mould filling patterns

- Part undercuts

- Post-moulding distortions

- Mating parts clearance

By addressing these factors during the design phase, we can significantly enhance the manufacturability and overall performance of the parts, saving customers valuable time and money.

Get in touch about Moldflow Analysis

Utilising only the latest analysis software, our engineers are equipped to optimise your designs to the highest standards, capable of turning your concepts into production-ready designs within a matter of days.