Sliding Core Tooling

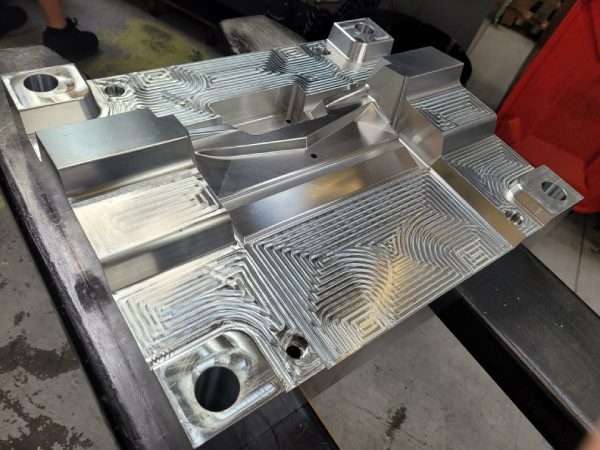

What is Sliding Core Tooling?

Sliding Core Tooling is a sophisticated injection mould design that incorporates movable sections or ‘cores’ to create complex geometries and features in moulded parts, such as undercuts or recesses, which cannot be moulded with fixed tooling alone.

This technique allows for the production of intricate designs with greater flexibility and precision.

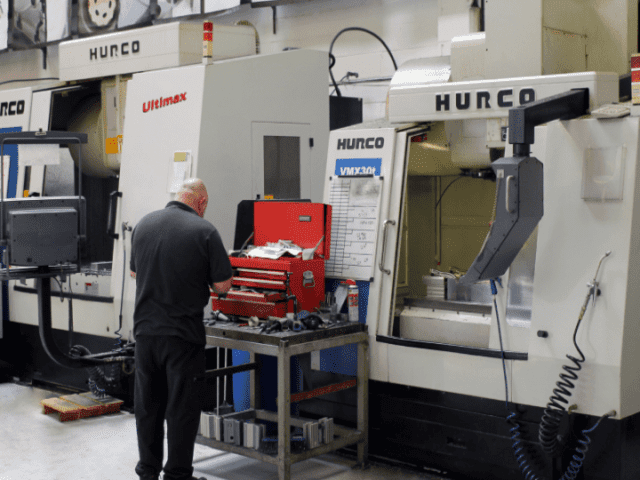

Why Choose Alliance Tooling for Sliding Core Tooling?

Alliance Tooling’s deep expertise in Sliding Core Tooling is instrumental in successfully executing projects requiring complex moulding capabilities.

Our team’s proficiency ensures that each tool is meticulously designed and engineered to achieve optimal functionality and reliability, enabling the efficient production of high-quality, detailed components.

Need help with Sliding Core Tooling?

Our experience with sliding core mechanisms enhances our ability to tackle challenging mould designs, ensuring seamless production processes and superior final products for our clients.

Get in touch to see how we can help you.