Quality

Quality Guaranteed

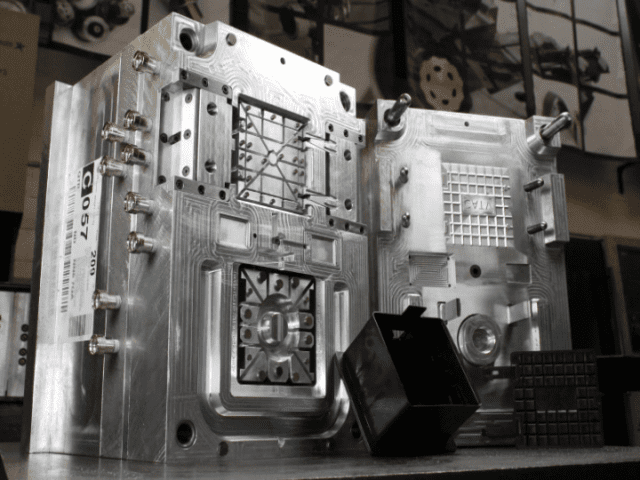

At Alliance Tooling, our unwavering commitment to manufacturing excellence is reflected in the superior quality and craftsmanship of every tooling project we undertake.

Central to our company ethos is a robust Quality Assurance (QA) culture that permeates every aspect of our operations, ensuring that precision, reliability, and attention to detail are hallmarks of our work.

Every tool we manufacture comes with a real shot-life guarantee, so you can rest easy knowing you’re partnered with a reputable toolmaker you can trust, manufacturing moulds made to last.

Customer Focus

Customer service is not just an extension of our business; it is the foundation.

We believe in building lasting relationships with our clients, understanding their needs, and delivering solutions that meet and exceed their expectations.

Our dedication to excellence is matched by our commitment to sustainability and environmental responsibility, as demonstrated by our adherence to international standards.

Looking for an Expert Injection Moulding Partner?

Accreditations

Proudly holding ISO 9001 and ISO 14001 certifications, along with recognition from EcoVadis and Sedex, Alliance Tooling is committed to a culture of quality management, environmental sustainability, and ethical business practices.

These accreditations are not just badges of honour but reflect our ongoing dedication to continuous improvement, operational excellence, and responsible sourcing, all while working towards a more sustainable future.

Learn more about what these accreditations mean for our customers and our processes on our accreditations page.

Trade Associations

Alliance Tooling is an active member of the UK and Irish toolmaking industry, holding a variety of memberships or associations with leading trade bodies in the sector:

In choosing Alliance Tooling, our clients gain a partner genuinely invested in their success, backed by internationally recognised standards that guarantee the highest quality and service levels.

Dedicated Quality Facilities

Alliance Tooling operates a dedicated temperature-controlled quality control facility with full CMM (coordinate measurement machine) measurement and inspection equipment. This facility is used to inspect and test parts for compliance before sample approvals and full-scale production.

As well as providing the manufacturing environment to fulfil projects to the highest standards, Alliance can test, measure and inspect all outgoing tools and mouldings in-house, ensuring all components and assemblies meet the highest quality standards before reaching the customer’s production line.

Additionally, we are able to provide full material traceability backed up with supplier certificates of conformity and, if required, complete Initial Sample Inspection Reports.

Learn more about these facilities and the advantages they bring to customers on our Tool Trialling service page.

New for 2023 is our dedicated validation centre for medical tooling. Following significant recent investment, this state-of-the-art facility accommodates all new tooling and machinery for our medical clients, streamlining the validation process for the most IP-sensitive projects.

Get in touch.

Our experience with the whole manufacturing process enhances our ability to tackle challenging mould designs, ensuring seamless production processes and superior final products for our clients.

Get in touch to see how we can help you.